Description

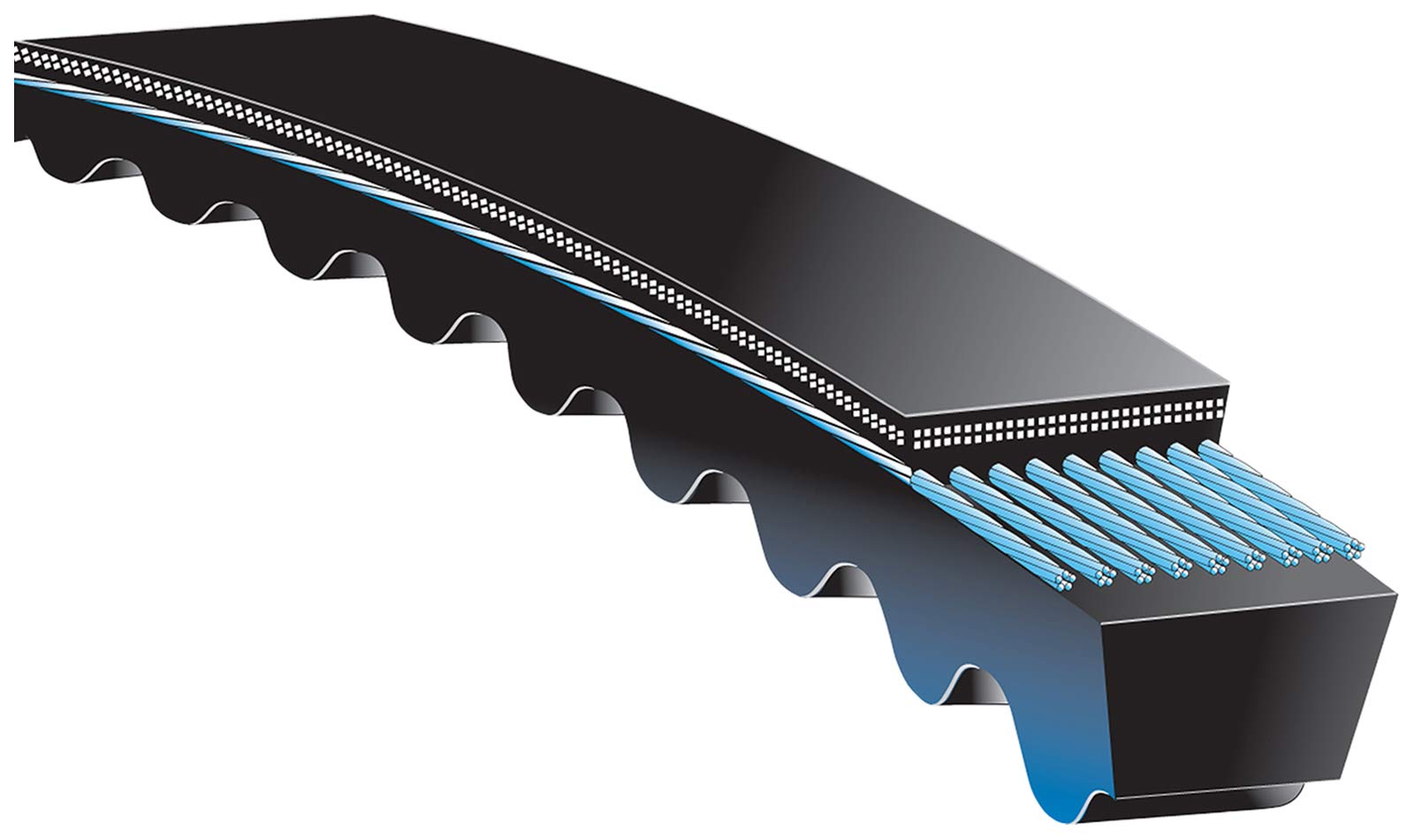

Cogged V-belts have grooves across the width of the belt to dissipate heat. These standard and cogged V-belts are categorized by the dimensions of their cross section and features that impact performance.

These cogs serve several crucial purposes:

Reduced Bending Stress: The cogs allow the belt to flex more easily around smaller pulleys, reducing bending stress and increasing belt life.

Enhanced Grip: The cogs create more surface area, improving the grip between the belt and the pulley, especially important in high-torque applications.

Cooler Operation: Improved flexibility and reduced friction lead to lower heat generation, enhancing the overall efficiency of the power transmission system.

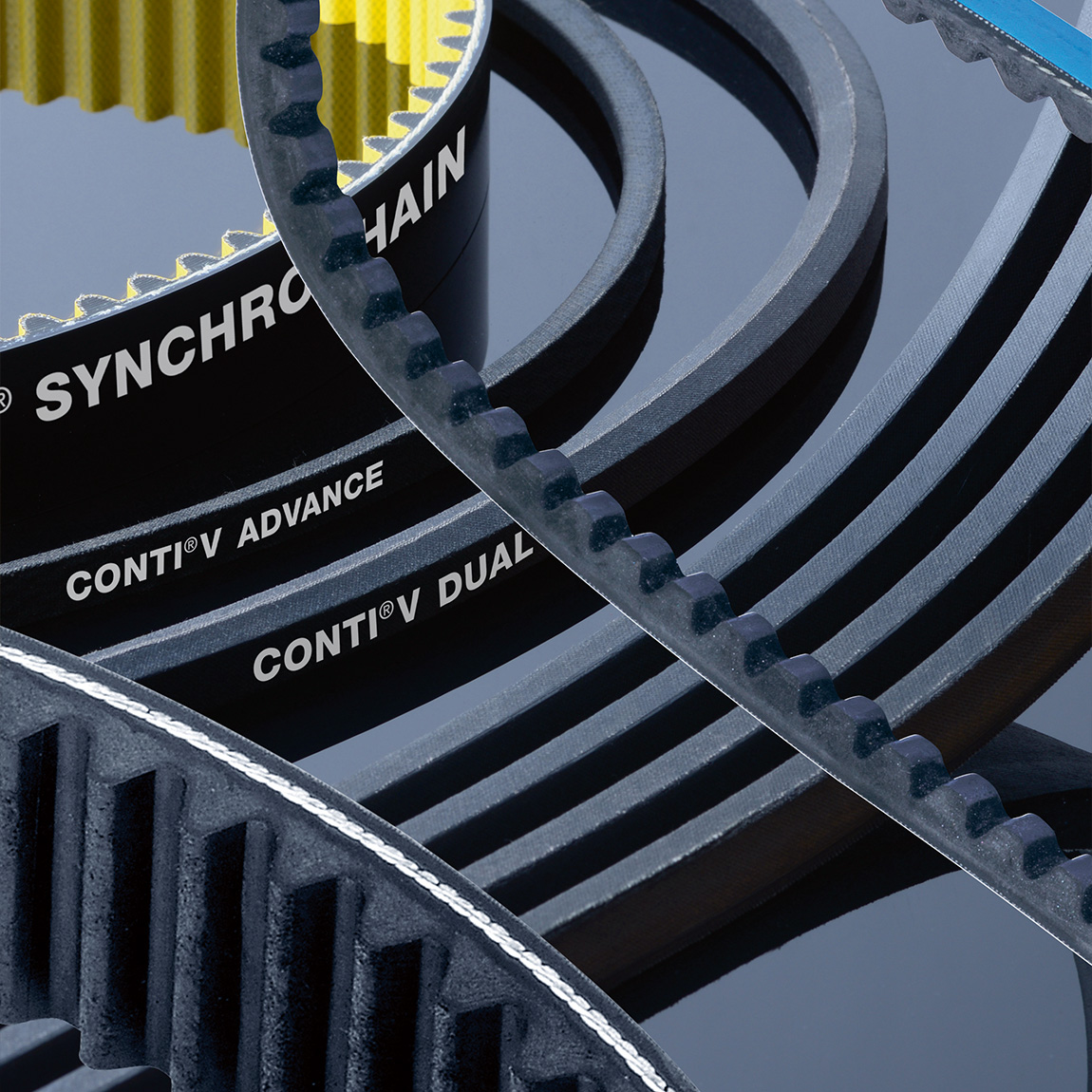

Our Cogged V-Belt collection includes various sizes and sections, such as 3VX, 5VX, AX, BX, and CX. These belts offer exceptional performance in demanding environments and high-torque applications, making them a favorite among industries that require precision and reliability.

In conclusion, whether you’re looking for the reliable simplicity of Standard V-Belts or the enhanced performance of Cogged V-Belts, MDS of Michigan has you covered. Our wide range of options ensures that you’ll find the perfect belt to keep your machinery running smoothly and efficiently.