Description

V-belts transmit mechanical power efficiently between different parts of a machine. They are commonly on automobile engines to drive accessories, such as the air conditioning compressor, power steering pump, alternator, and fan. A v-belt has a trapezoidal cross-section and comes in various types depending on their dimensions. This article discusses the constructional features, types, and main applications of v-belts.

What is a v-belt

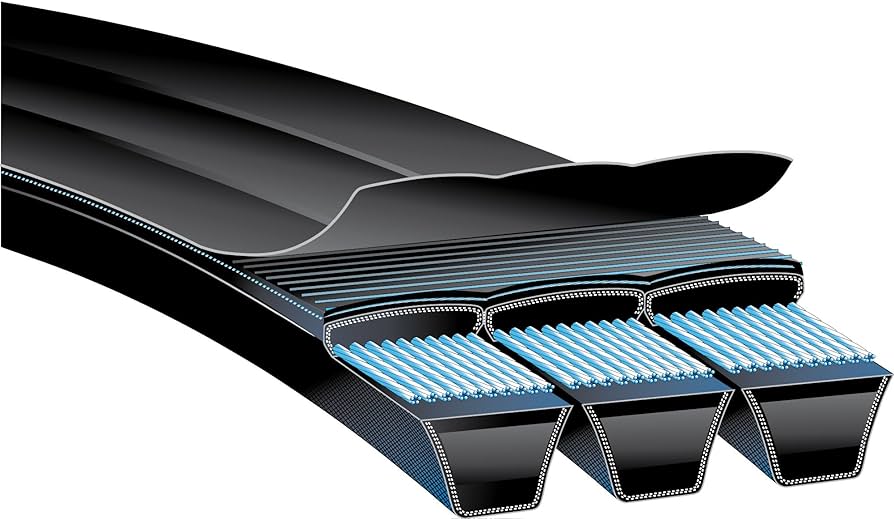

A v-belt is flexible and transmits power from one shaft to another. As seen in Figure 2, a v-belt has a trapezoidal cross-section. The wedge-shaped belt fits perfectly into the wedged groove of a pulley. Due to this good fit, v-belts transmit more force than flat belts. Also, pulley systems that use v-belts typically have pulleys near one another. Therefore, the system is compact.

Constructional features of a v-belt

A v-belt consists of the following parts:

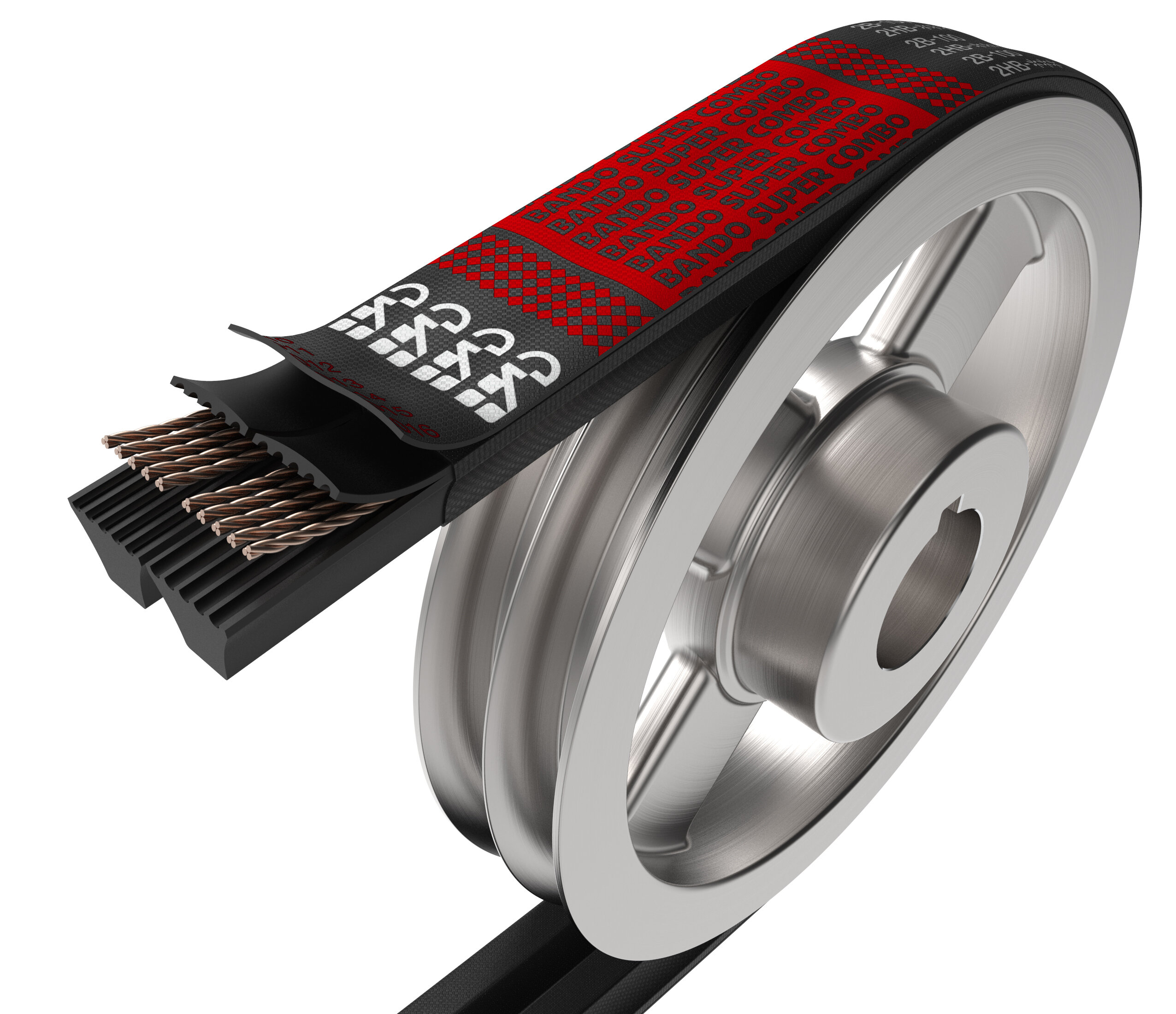

Steel wires: Steel wires (Figure 2 labeled A) have no joints between them and are of the endless type. These wires provide the necessary strength and reinforcement to the v-belt for torque transmission.

Base rubber compound: A rubber compound (Figure 2 labeled B) acts as the core surrounding the steel wire providing shape to the v-belt. The rubber compound (an elastomer) also acts as a medium of compression to absorb shocks during the transmission of power.

Protective cover: The protective cover (Figure 2 labeled C) is a layer of plastic that provides sufficient tolerance for the rubber against the high temperature that is generated during the v-belt movement.

V-belts have several profile (i.e., cross-section) options. While all of them feature the basic trapezoidal shape, each one has different dimensions. The main industry standards are:

Classical. This standard was developed in the 1930s. It now comes in six sizes (A, B, C, D, E and Z).

Narrow. Compared to the classical standard, this standard has more steeply angled sidewalls, which enhances wedging and load-carrying capacities. It comes in three sizes (3V, 5V, and 8V).

Metric. This standard complies with international standards (e.g., ISO and DIN). Also, the Classic belts have international standards (DIN 2215) making it suitable for machinery belts employed in other countries. It comes in many sizes (XPZ SPZ, XPA SPA, XPB SPB, XPC SPC, 10X, 13X, and 17X).