Description

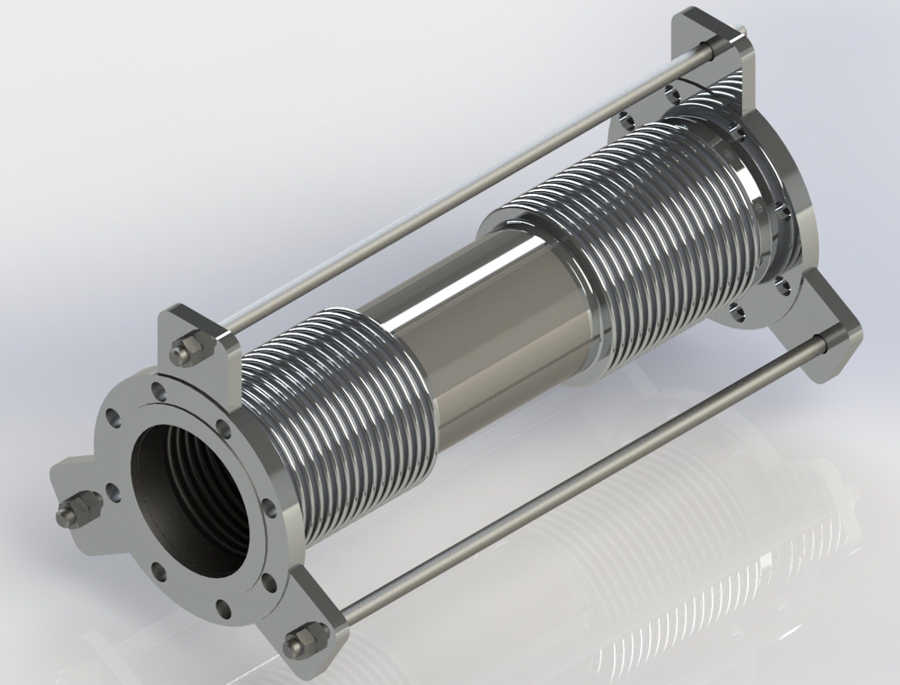

The Universal Pipe Expansion Joint Consists Of Two Bellows Separated By A Pipe Section Or Spool. The Primary Purpose Of This Arrangement Is To Have A Unit Which Will Accept Large Amounts Of Lateral Deflection. The Amount Of Lateral Deflection They Can Accept Is A Function Of The Amount Of Angulation Each Bellows Can Absorb And The Distance Between The Bellows. For A Given Bellows Element, The Amount Of Lateral Deflection Capability Can Be Increased Or Decreased By Simply Changing The Length Of The Center Spool.Since Deflections Are Usually The Result Of Piping Thermal Expansion, And Universal Expansion Joints Are Usually Long, The Thermal Expansion Of The Entire Unit’S Length Is Accepted As Compression By The Two Bellows Elements. In This Way, The Overall Length Of The Unit Does Not Change When The Piping Is Heated.Features Absorbs Large Amounts Of Lateral Deflection Unit Length Does Not Change With Heat Eliminates Pressure Thrust Load Tie Rods Not RequiredInstalationThe Necessary Steps For Installing All Pipe Expansion Joints Shall Be Pre-Planned. The Installers Shall Be Made Aware Of These Steps As Well As The Installation Instructions Furnished By The Manufacturer. The Most Critical Phases Of The Pipe Expansion Joint Installation Are As Follows.Care Shall Be Exercised To Prevent Any Damage To The Thin Bellows Section, Such As Dents, Scores, Arc Strikes And Weld Spatter.No Movement Of The Pipe Expansion Joint (Compression, Extension, Offset, Rotation And Especially Torsion) Due To Piping Misalignment, For Example, Shall Be Imposed Which Has Not Been Anticipated And Designed Into The Movement Capability Of The Pipe Expansion Joint. If Such Movements Are Imposed, They Can Result In System Malfunction, Damage To The Bellows Or Other Components In The System. Specifically, Cycle Life Can Be Substantially Reduced, Forces Imposed On Adjacent Equipment May Exceed Their Design Limits, Internal Sleeve Clearances May Be Adversel