Description

Product Code : 10

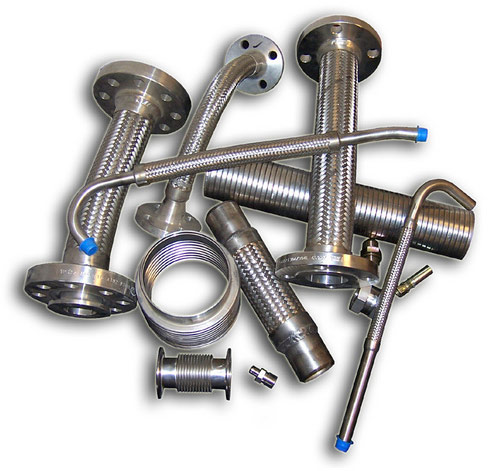

SS corrugated Hoses

Technical Data

|

Nominal |

Without braid |

With single braid |

With double braid |

|||

|

Max working |

Test |

Max working |

Test |

Max working |

Test |

|

|

6 |

4 |

6 |

100 |

150 |

160 |

240 |

|

10 |

4 |

6 |

90 |

135 |

144 |

216 |

|

12 |

3 |

4.5 |

80 |

120 |

128 |

192 |

|

16 |

3 |

4.5 |

70 |

105 |

112 |

168 |

|

20 |

2 |

3 |

64 |

96 |

102 |

153 |

|

25 |

2 |

3 |

50 |

75 |

80 |

120 |

|

32 |

1.5 |

2.3 |

40 |

60 |

64 |

96 |

|

40 |

1.5 |

2.3 |

30 |

45 |

48 |

72 |

|

50 |

1 |

1.5 |

28 |

42 |

44 |

66 |

|

65 |

1 |

1.5 |

24 |

36 |

38 |

57 |

|

80 |

1 |

1.5 |

18 |

27 |

28 |

42 |

|

100 |

0.8 |

1.2 |

16 |

24 |

26 |

39 |

|

125 |

0.6 |

0.9 |

12 |

18 |

20 |

30 |

|

150 |

0.6 |

0.9 |

10 |

15 |

16 |

24 |

|

200 |

0.5 |

0.75 |

8 |

12 |

12 |

18 |

Note

The above Technical details are subject to change without notice.

We can also supply the above Hoses for higher pressures.

The above values apply only to Braided Hoses and Assemblies at ambient temperature

Flexible Metallic Hoses:

Manufactured with Carbon Steel, S.S. and Brass of type 321, 304, 304L, 316, 316L and flexible tubes of Stainless Steel .

Specifications:

ASSEMBLES AND HOSES

Let us fabricate and helium leak test your hose assembly as a complete package with a gasket and/or an Epsilon Coupler, giving you assurance that your system is leak-free.

- Certified Welders ASME B31.3 Section 9

- Custom Fittings Available

- Metal hose assemblies & custom fittings available

- Helium Leak Testing with Mass Spectrometer

- For piping installations requiring temps to 1500o, vibration absorption, Chemical resistance and no effusions.

- Pump Connectors

- Flex lines (flexline) flexible metal hose assemblies

- Bellows

- Expansion joints

- Cryogenic metal hose assemblies

- Annular and Helical metal hose assemblies

- Tubular and Braided metal hose assemblies

- 321, 316 Stainless, and specialty metals including Monel and Inconel

- Oxygen Service Cleaning available

- Custom length hose assemblies from 1/4″ ID – 14″ ID

- Stocking fabricator/manufacturer

Sizes: 1/4” to 12”