Description

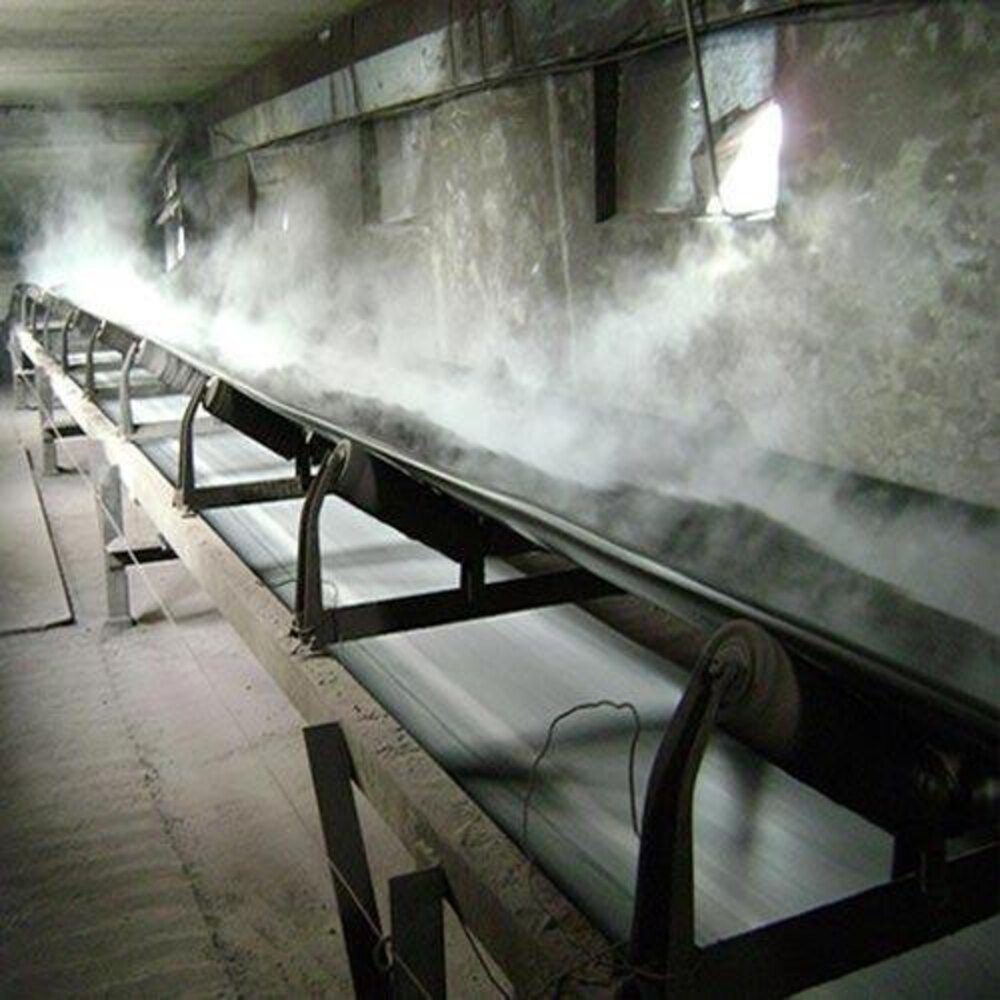

Heat Resistant Rubber Textile Conveyor Belts

Under normal circumstances, a normal conveyor belt works perfectly well up to 80 ° C. Excess heat can result in severe harm and a reduction in the life of the conveyor belt carcass.

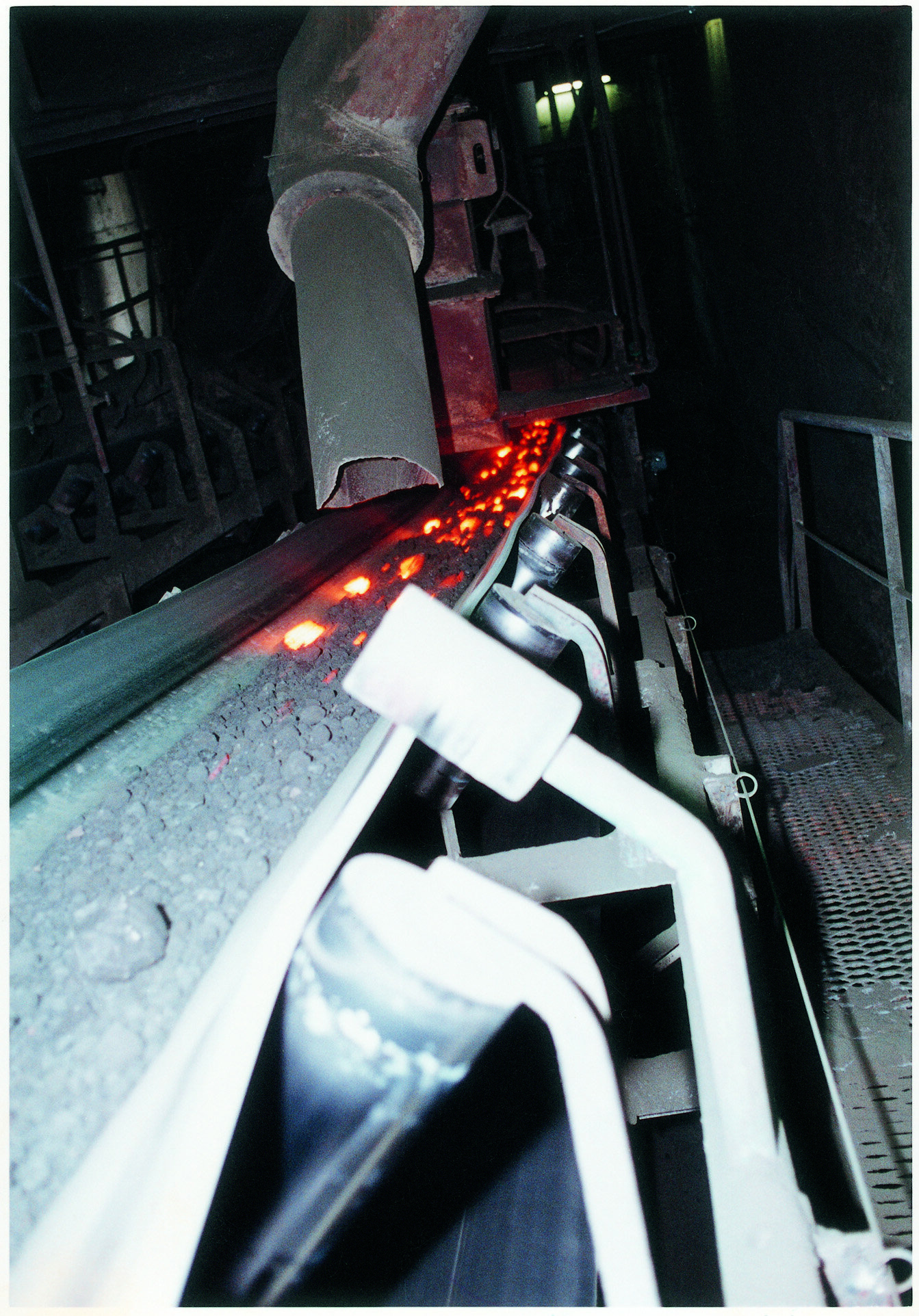

The unique rubber compound we use avoid belt structure deformation and is extremely resistant to warm metals, like glue, steel or sand. To ensure the necessary thermal strength, EPDM or chlorobutadiene gum is used.

We offer various thermal resistance elastomers as a base of our heat resistant rubber conveyor belts:

T1–MEDIUM HEAT Resistance 150 ° C (maximum 180 ° C)

T2–HEAT Resistance 180°C (peak 200 ° C)

T3–ULTRA HUGH HEAT resistance 200 ° C (peak up to 400 ° C) for steady application temperatures.

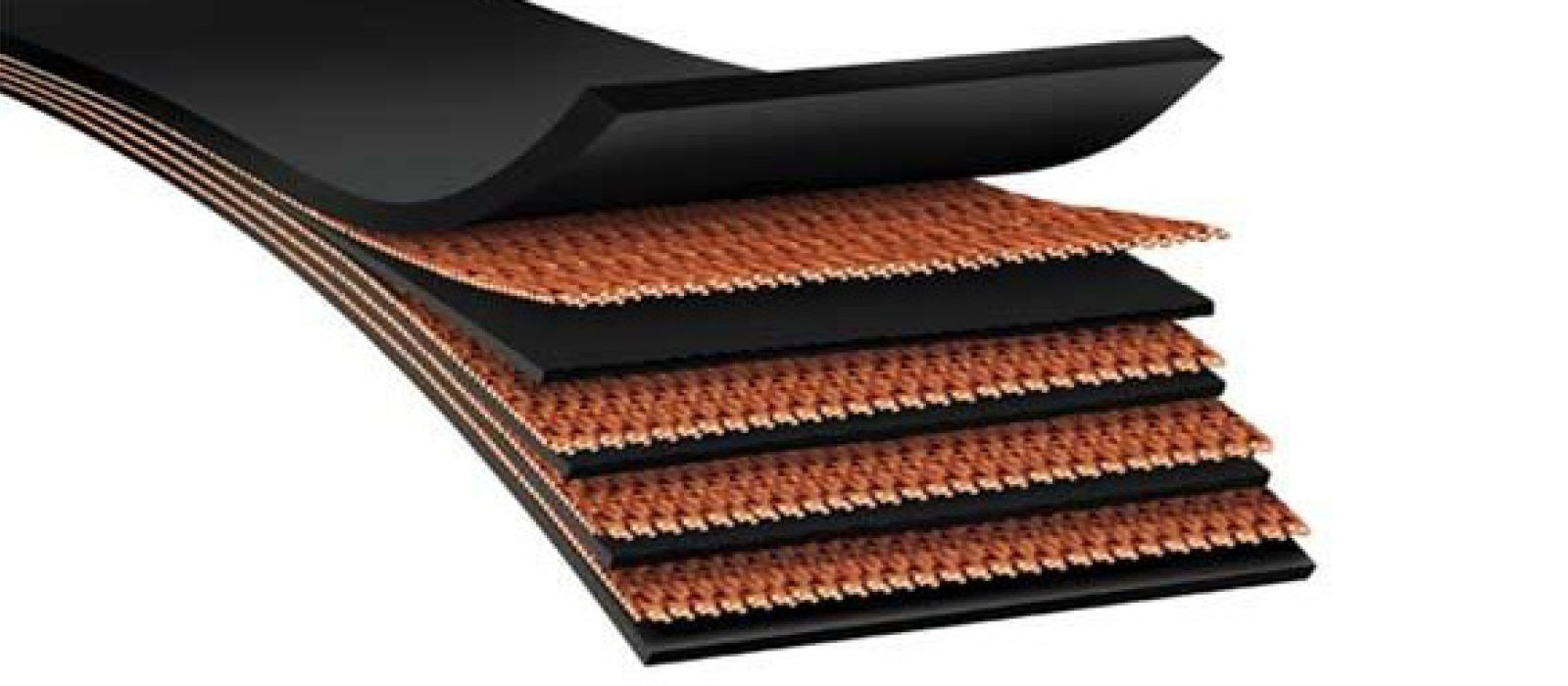

The rubber compound functions as a life-saving layer for the carcass. In addition, the density of the rubber cover top and bottom also contributes to safeguard the heat resistant conveyor belt’s life.

Heat Resistant Rubber Textile Conveyor Belts are highly resistant to hot cement, steel or sand material. The cover of this kind transport belts comprises of a unique rubber compound with high adhesive resistance, cut strength, high elongation at break and outstanding thermal protection.

Heat resistance differs with various elastomers. Heat-resistant conveyor belts manufactured according to DIN 22102 can transport material up to 250 ° C at a constant temperature of 200 ° C.

Thickness should therefore always be taken into account – if you are not sure – our service group will assist and advise you.