Description

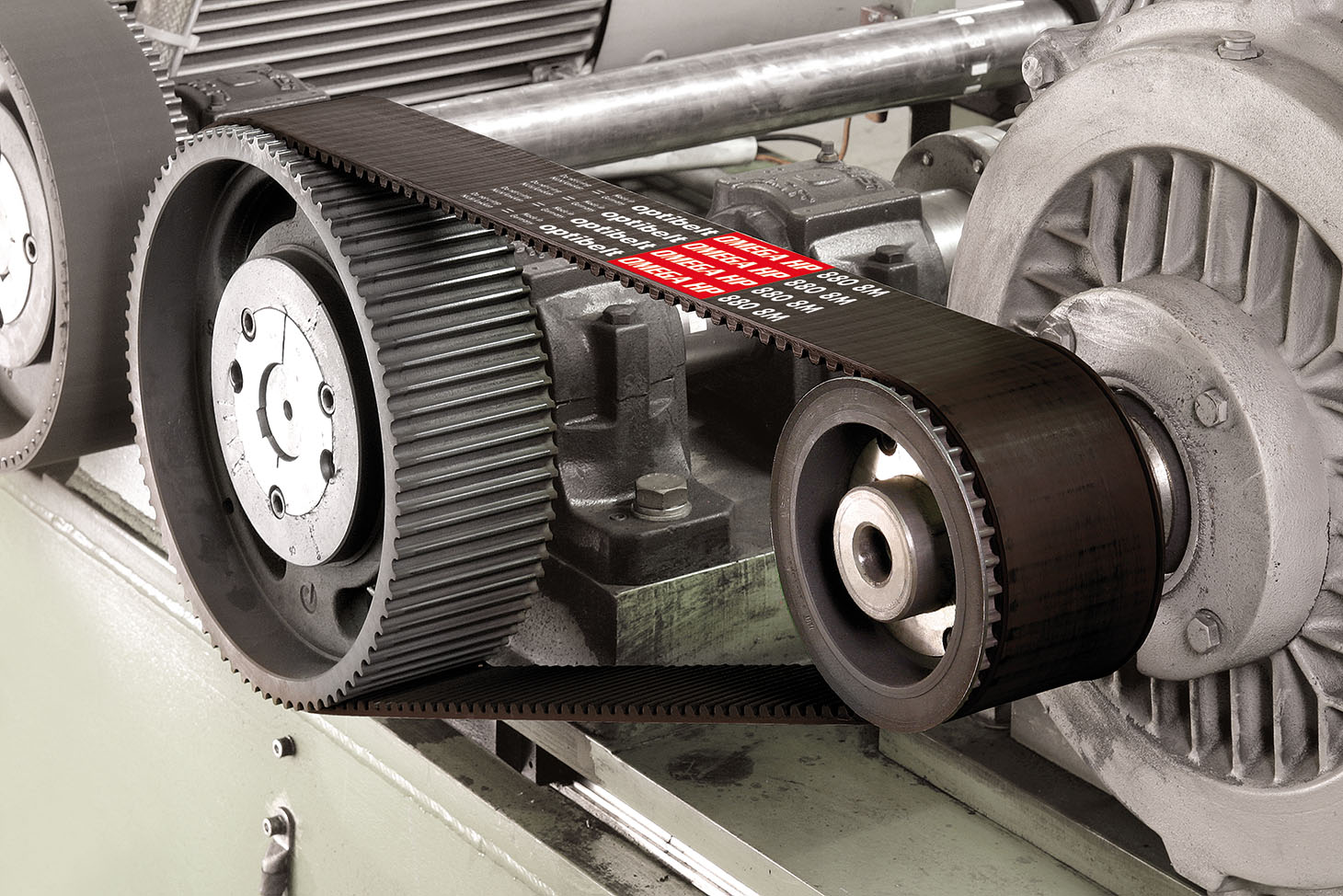

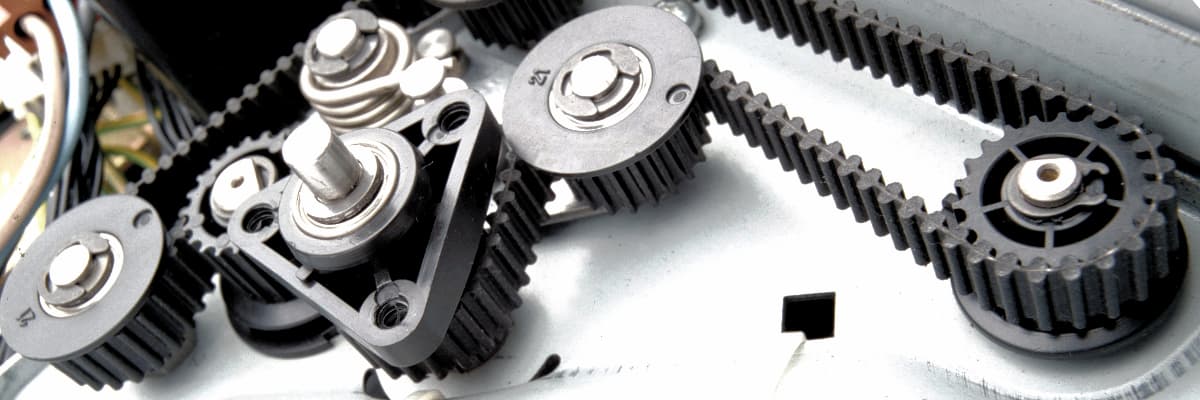

The Double-sided Timing Belts have the same performance as Timing Belts and SUPER TORQUE Timing Belts. They have teeth on both sides of the belt and can be used for multi-axis transmission and double-sided drive.

The standard specification of the Double-sided Timing Belt G has the same performance as the Timing Belt G and SUPER TORQUE G. It has teeth on both sides of the belt and can be used for multi-axis transmission and double-sided drive.

Double-sided Timing Belt U has the same performance as Timing Belt U. It has teeth on both sides of the belt and can be used for multi-axis transmission and double-sided drive. The attractive appearance and less rubber dust dispersion enable use in places where clean environment is required.

Double-toothed belts are used for drives with axles that rotate in opposite directions.

The most common types are available in the double-toothed version, both in PU and neoprene.

In addition, it is possible to make special double-toothed belts in PU. A standard toothed belt is coated with 90 ° Shore PU in which the desired tooth shape is milled. In this way it is even possible to create two different tooth shapes on one toothed belt.

Ask our sales team for the possibilities.